Can be installed in your laboratory or plant for samples or production.The Cornell Versator Machine Company’s Cornell Versators: Minimal product loss during operation.The Cornell Machine Company can offer Cornell Versators for in-plant trials on a monthly rental basis. Few spare parts subject to wear and easy access to interior parts for inspection and cleaning.Material can be discharged from vacuum chamber by operating design. Additional pumps for feed and discharge are not necessary in most installations.Continuous operation (no timed cycle) and can be installed in-line or used for batch processing.Design allows all of the processed material to be exposed in a thin film to high vacuum.Heat sensitive and shear sensitive products can be processed.Process virtually any pourable or pumpable liquid - hot or cold - from water to hot chewing gum.The principle of operation is the same for each Versator model size.Efficient mixing, blending, homogenization, dispersion, emulsification, removal of moisture or distillation of residuals as a simultaneous secondary benefit.Removal of entrapped air, foam, or gas from liquids under high vacuum.

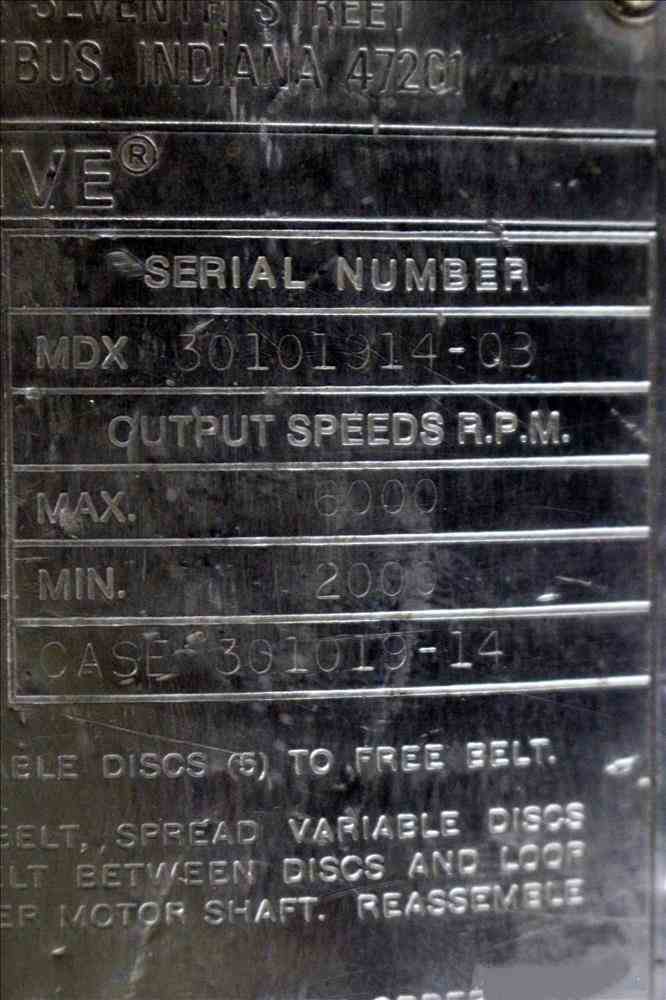

The Versator’s operation is accomplished in a fraction of a second. The Versator Chamber does not fill the liquid stays within the Versator Disc. The air, foam, or gas removed from the liquid exits the system through the vacuum pump's discharge or exhaust. When the deaerated liquid reaches the inner edge of the Versator Disc, the rotation forces the liquid up a special pipe assembly which fits closely to the surface of the Disc and out of the Versator Chamber. While the liquid travels across the Disc, the high vacuum draws off the entrapped bubbles from the thin film. The rotation of the Versator Disc centrifuges the thin film of liquid across the interior surface of the Versator Disc. When the flow of aerated liquid passes through this clearance, it forms an even thin film of liquid. The vacuum draws the aerated liquid to the Versator and into the Feed Assembly.Īt the end of the Feed Assembly, the Spreader Ring has a close clearance with the inside surface of the Versator Disc. The vacuum is typically 28-29" Hg and the disc speed may range from 1200-6000 RPM depending on the Versator model. The Versator's principle of operation relies on the spreading of a thin film of aerated liquid on the inside of the rotating Versator Disc under high vacuum to remove entrapped air, foam, or gas.ĭuring operation, the Versator chamber is under high vacuum and the Versator Disc is rotating.

0 kommentar(er)

0 kommentar(er)